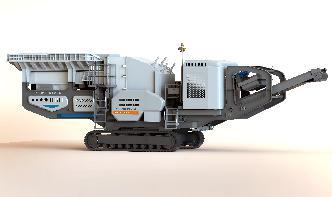

CNC Shot Peening Machines Equipment | Engineered Abrasives.

Our CNC shot peening machines provide even, exact finishes over the entire surface area and can accommodate large airframe and structural work pieces. Engineered Abrasives® experienced staff will design and manufacture a CNC shot blasting machine that will meet your most demanding appliion requirements, providing high quality, efficient blasting for your aerospace or specialty parts ...