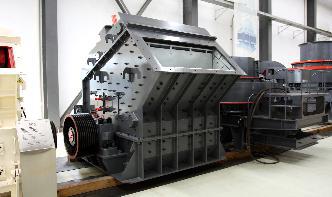

Concrete Manufacturing Process | Crusher Mills, Cone ...

The Manufacturing Process – Trinidad Cement Limited. TCL uses what is known in the industry as a wet process technology for the manufacture of cement.